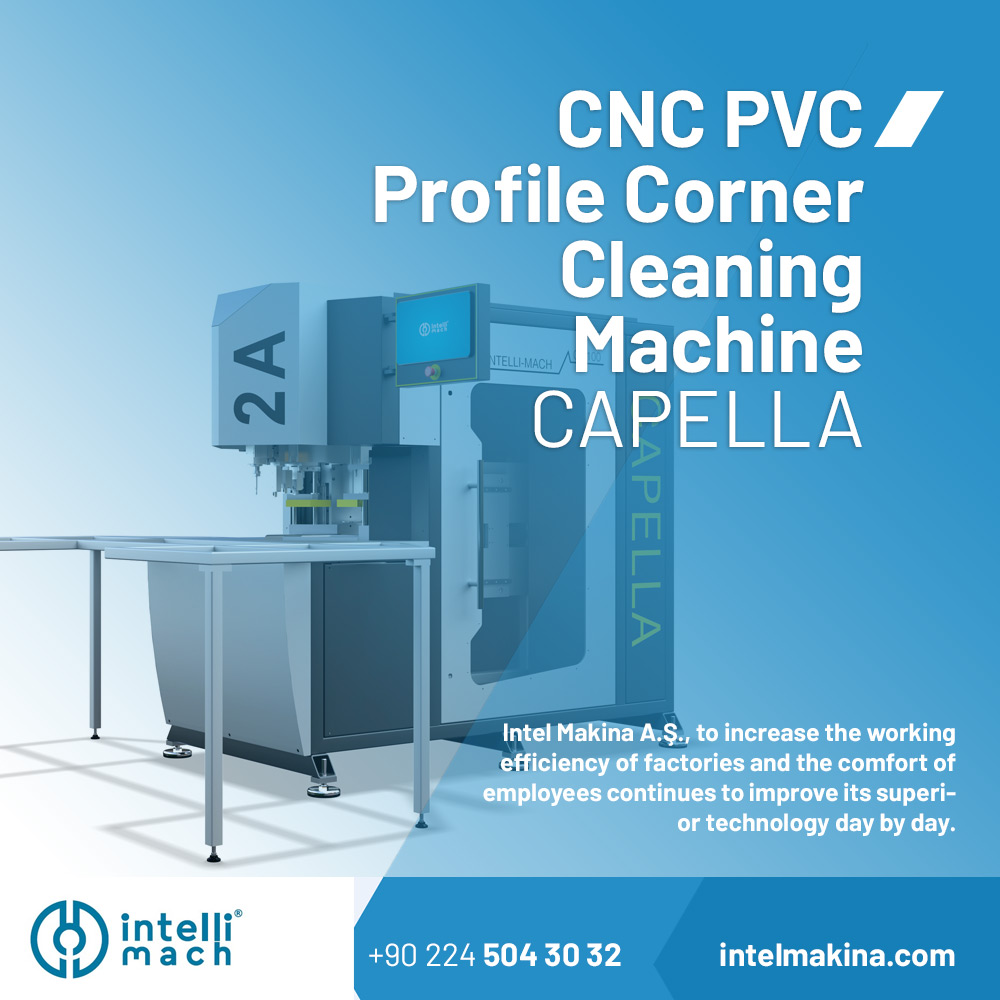

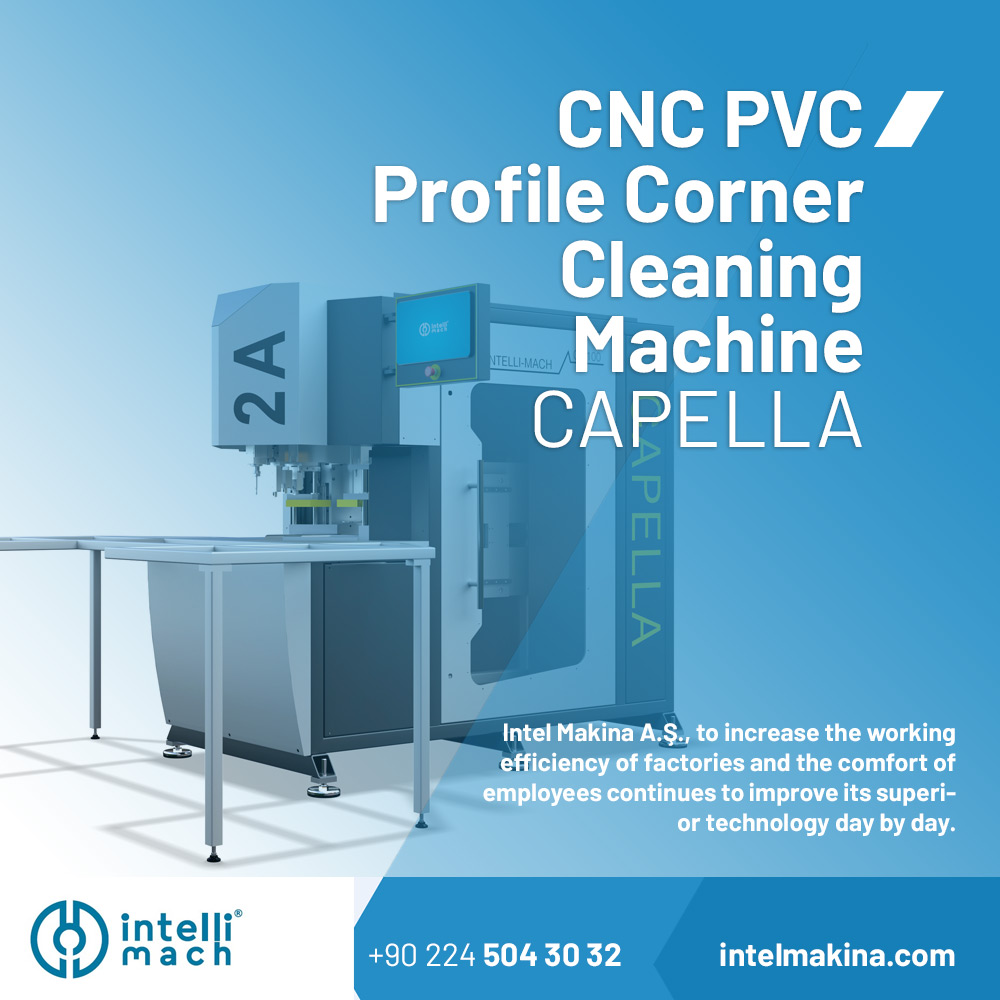

upvc cnc corner cleaning machine

A UPVC CNC corner cleaning machine is a specialized piece of equipment used in the manufacturing and processing of uPVC (unplasticized polyvinyl chloride) windows and doors. uPVC is a common material for window and door frames due to its durability, low maintenance requirements, and energy efficiency. To ensure the quality and performance of uPVC windows and doors, it’s important to clean and prepare the corners and edges of the profiles before assembly and installation. This is where a CNC corner cleaning machine comes into play.

Here are some key features and functions of a uPVC CNC corner cleaning machine:

- Corner Cleaning: The primary function of this machine is to clean the corners of uPVC window and door profiles, removing excess material, burrs, and any imperfections to ensure precise and smooth joints.

- CNC Control: CNC (Computer Numerical Control) technology is used to program and control the machine’s movements with high precision. This allows for consistent and accurate corner cleaning.

- Multiple Cleaning Tools: CNC corner cleaning machines typically come equipped with various cutting and cleaning tools to handle different profile shapes and sizes. These tools may include milling cutters, saw blades, and brushes.

- Adjustable Parameters: Operators can often adjust parameters such as tool speed, feed rate, and cutting depth to accommodate different uPVC profiles and cleaning requirements.

- Dust Extraction: These machines often have dust extraction systems to collect the debris generated during the cleaning process, ensuring a clean and safe working environment.

- Efficiency: CNC machines are known for their efficiency and speed. They can process uPVC profiles quickly and consistently, improving production efficiency.

- Quality Control: By using a CNC corner cleaning machine, manufacturers can maintain high-quality standards for their uPVC windows and doors, resulting in better overall product performance and aesthetics.

- User-Friendly Interface: Many CNC machines feature user-friendly interfaces that make it easy for operators to set up the machine and monitor the cleaning process.

Overall, a uPVC CNC corner cleaning machine plays a crucial role in the manufacturing of high-quality uPVC windows and doors by ensuring that the corners of the profiles are properly cleaned and prepared for assembly. This not only enhances the appearance of the final product but also improves its durability and performance.

Makinası